Fully detailed and controlled film casting process

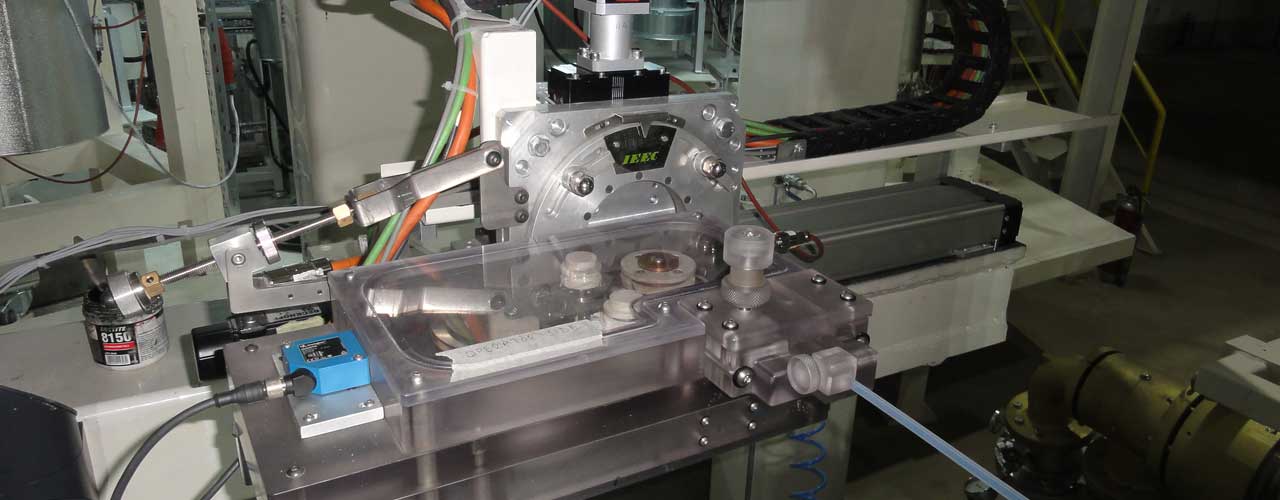

Our Band Pinning systems produce high quality Bi-axially Oriented Polyester (BoPET), film at the fastest possible chill roll speeds, while maintaining the best possible transparency and other physical attributes. High quality film is the result of a perfectly controlled casting process. One of the most critical features of the casting process is an extremely precise and flexible pinning system. Most commercially available pinning systems utilize the principle of generating an electrostatic effect to pin the extruded melt on to the chill roll by causing ionization of air, thus eliminating air entrapment between melt & chill roll. The elimination of air entrapment creates extremely close contact between the melt and the chill roll, resulting in a virtually clear cast film, suitable for subsequent orientation at maximum line speeds.

Key Features

- Our precision Moving Band Pinning System can be customized to suit Cast Film lines equipped with older methods of pinning, such as wire pinning.

- We offer a comprehensive replacement /retrofit service for BoPet lines, comprisingSite Evaluation, Fixture Design, Installation and Start up.

- Band Unwinding and Winding Unit.

- Mounting elements, for Unwinder and Winder, with mechanisms for adjustment of Band angle relative to the chill roll.

- Two axis (x and y), gantry, permitting precise positioning of the Unwinder and Winder relative to the melt touch down point.

- A control panel comprising: High Voltage generator, Blade (band), heating generator, servo controls for Unwinding, Rewinding station. Servo controls for the two axis gantry system, and a touch screen panel that enables complete control of the pinning system.

- Remote stations are also provided for user mounting close to the Unwinder and Winder units, facilitating convenient system control by the operator.

- Unique "Spark Arrestor System".

Technical Details

High Voltage Generator

- Mains voltage: 415VAc +/- 5%

- Mains frequency: 50Hz / 60Hz +/- 5%

- Inverter output frequency: 10 KHz – 20 KHz

- Inverter output voltage: 15kV

- Inverter output current: 30 mA max

- Recovery time: Less than 1 millisec

- Ripple factor: 0.1% peak - peak

Blade Heating Generator

- Mains voltage: 415VAc +/- 5%

- Mains frequency: 50 Hz / 60Hz +/- 5%

- Inverter output frequency: 10 KHz – 20KHzp

- Inverter output voltage: 50 Volt

- Inverter output current: 10.0 Amp max