Increasing surface tension of substrates through advanced technology

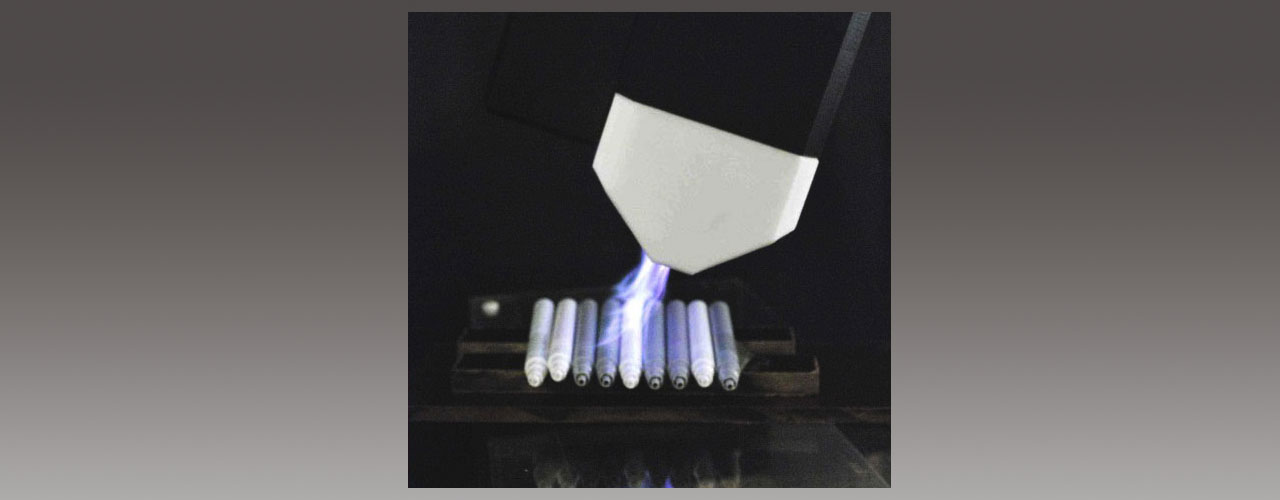

The process of increasing Surface Tension (dynes/cm) of a substrate by exposing it to an Atmospheric Plasma Flame is called Atmospheric Plasma Treatment. Non-contaminated, refrigerated dry, moisture free, and oil-free compressed air is passed through High Voltage at High Frequency. Air molecules get ionized and air reaches fourth stage of matter (Plasma), creating Atmospheric Plasma.

Applications

Automobile Industry

Head lights, door sealing profiles, decorative trim, switch components, control unit housings, bumpers.

Printing Industry

For inkjet Printing on bottles, caps, wires and cables, pipes, glass and other materials. For pad printing on pens, mobile covers, switches, switch boards etc.

Medical Devices

Dialysis machines, disposable syringes, catheter, ampoules, contact lenses, test tubes, petri dishes.

Glass Industry

Window seals, window frames, printing on drinking glasses and bottles, perfume flacons.

Coating

Foil coating, flocking, laminating.

Adhesive Technology

Plastic sheets, furniture coatings.

Laminating

Instrument panels, interior door coverings, car boot linings.

Technical Specifications

- Power Output: 800 Watts

- Voltage Output: 30kV

- Optimal Treating Distance: Minimum 25 mm

- Maximum: 45 mm

- Treating Head Width: 90mm

- H.V. Cable & Air hose Length: 2m each

- Input Voltage: 230V, 50/60 Hz

- Input Current: 5 Amp

- Max Ambient Temperature: 45 degrees C

- Power Adjustment: 0-100%

- Blower Adjustment: 0-100%

- Net Weight: 41 kg