Dyne Testing

Procedure.

Surface tension is the property of a liquid arising from unbalanced molecular forces at or near the surface. If it is higher than the surface energy of a material, the liquid tends to form droplets rather than spread out. Another name for an ink's surface tension properties is 'wettability'. Surface tension is normally measured in energy units called dynes/cm. A dyne is the amount of force required to produce an acceleration of 1 cm/sec2 on a mass of 1g.

The dyne level of a material is called its surface energy. If the liquid has a dyne level lower than the material's surface energy, then the liquid will spread out over its entire surface in a uniform wet layer. If the ink's dyne level is equal to or higher than a material's dyne level, the liquid will become cohesive and tend to remain in droplets.

Surface test fluids were introduced to give an accurate measurement of graduated surface tension levels. The fluid is applied to the surface or substrate until a satisfactory dyne level is found.

In addition to our family of pre-filled dyne test pens, IEEC continues to offer dyne test solutions in bottles. As part of our standard inventory IEEC offers our ASTM D 2578 compliant dyne test inks from 30 to 70 dyne/cm.

TESTING PROCEDURE TIPS

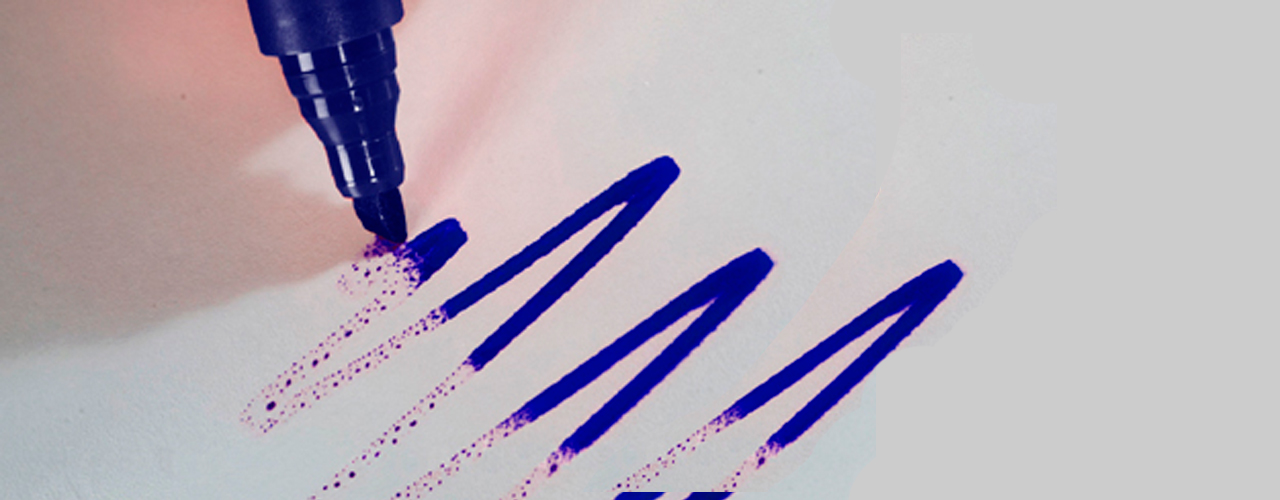

- Spread the test fluid from the felt tip pen or from the Dyne Solution bottle using cotton Swab lightly over an area of approximately 7 cm of the test specimen, noting the time it takes for the continuous film of ink to break into droplets.

- Breaking of the fluid into droplets in less than 2 seconds indicates a lack of wetting and a lower numbered test fluid should be tried.

- If the fluid remains intact for longer than 2 seconds, a higher numbered test fluid should be tried.

- The aim is to establish the lowest reading at an optimum dwell time of 2 seconds.

- Extreme care must be taken to ensure the film surface is not touched or contaminated in the areas in which the tests are to be made.

- We recommend the replacement of the inks regularly if the bottled inks are frequently opened to atmosphere.

- If bottled inks are exposed to the air on a daily basis: dispose of remaining inks after 3 months .

- If bottled inks are exposed to the air on a weekly basis: dispose of remaining inks after 6 months.

- If bottled inks are exposed to the air on a monthly basis: dispose of remaining inks after 6 months.

NOTE:

Disposal of dyne solutions is typically a locally regulated function. We recommend you contact your local municipality, or disposal service to learn how to properly dispose of any expired dyne solution.

While PBJ - Industrial Electronics Pvt. Ltd. believes the information contained herein is factual and the options expressed are those of qualified experts, this information is not to be taken as a warranty for which PBJ - Industrial Electronics Pvt Ltd assumes legal responsibility. It is provided solely for consideration, investigation, and verification.