Technical notes on Ozone Treatment System.

Technology & Technical Advantages.

Good bond strengths, high line speeds & reduced melt temperatures: Ozonater

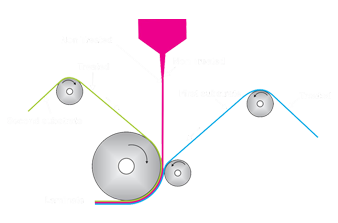

During the Extrusion Coating/Lamination Process, it is always a challenge to achieve good bond strengths as the Hot Melt Poly remains untreated during the treatment of primary and secondary substrates. IEEC's Ozonater is an Ozone Treatment System that is built to address this with ease. It treats the Hot Melt Poly coming out of the extruder just before it falls on the lamination drum. This increases the surface energy of the Hot Melt Poly and gives good bond strengths. Reduced melt temperatures help achieve high line speeds.

Technical Advantages

- Treatment possible up to a maximum width of 2 metres.

- Corrosion resistant paint.

- Use of oxygen to achieve high concentration of ozone.

- Avoid odor and off taste.

- Achieve low melt temperatures.

- High line speeds.

- Good bond strengths.

- May avoid the use of primer coating.

- Improve heat sealability.