Most innovative and efficient technology in extrusion coating: Ozogen 500

With emerging trends of packaging and improved demand of high quality products, we are committed to adopt these technologies to achieve better quality at high line speeds. Ozone Treatment is a significant step in that direction. When packaging uses extrusion coating, good bond strength is required between laminates. With consistent R & D and customer feedback, we developed "Ozogen-500" - an efficient technology in extrusion coating. Ranked alongside Corona and Flame Treatment as one of the three main treatment technologies in extrusion coating process, Ozone Treatment provides good bond strength, avoids odour and off-taste, while delivering efficient bond strengths at high line speeds.

How Hot Melt Poly is treated?

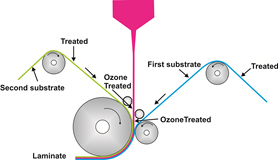

Ozogen-500 treats Hot Melt Poly by applying Ozone when coming out of the T-Die from the extruder.

Advantages of Ozone Treatment include:

Ozone Treatment, not only increases Surface Tension (Dyne/cm) of Hot Melt Poly coming out of the extruder but has more benefits, including:

- Reduced Melt Temperatures.

- Reduced Odor and Off Taste.

- Increased Line Speeds.

- Use of Primers Eliminated.

- Improved Heat Seal-ability.

Ozone helps achieve good bond strength without any high temperature oxidation:

Ozone is produced under strictly controlled conditions and exposed to the Hot Melt Poly, deep in the nip area at the contacting surface. As it decomposes to oxygen molecule and nascent oxygen, it acts as a strong oxidizing agent. Research proves that if Ozone is applied near the nip at 4 cm from the Hot Melt Poly, maximum adhesion can be achieved.

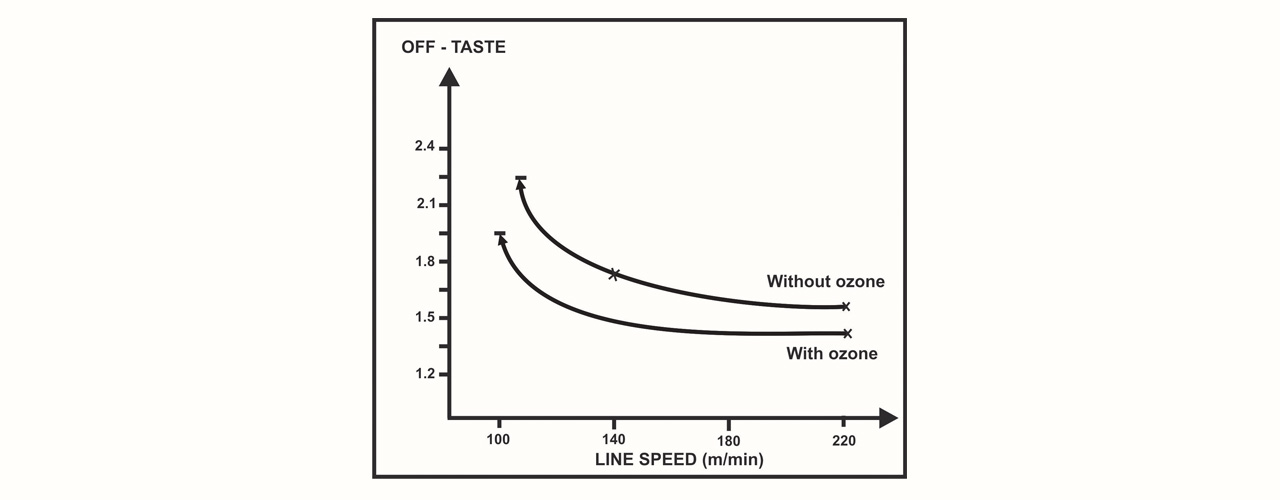

Ozone reduces off-taste:

Excessive melt and oxidation degrades polymer, which results in odour or off-taste. This can be a critical issue when used for food packaging. With ozone, equal bonding levels can be achieved irrespective of line speed, and off-taste or odour is significantly reduced.